Jump to section

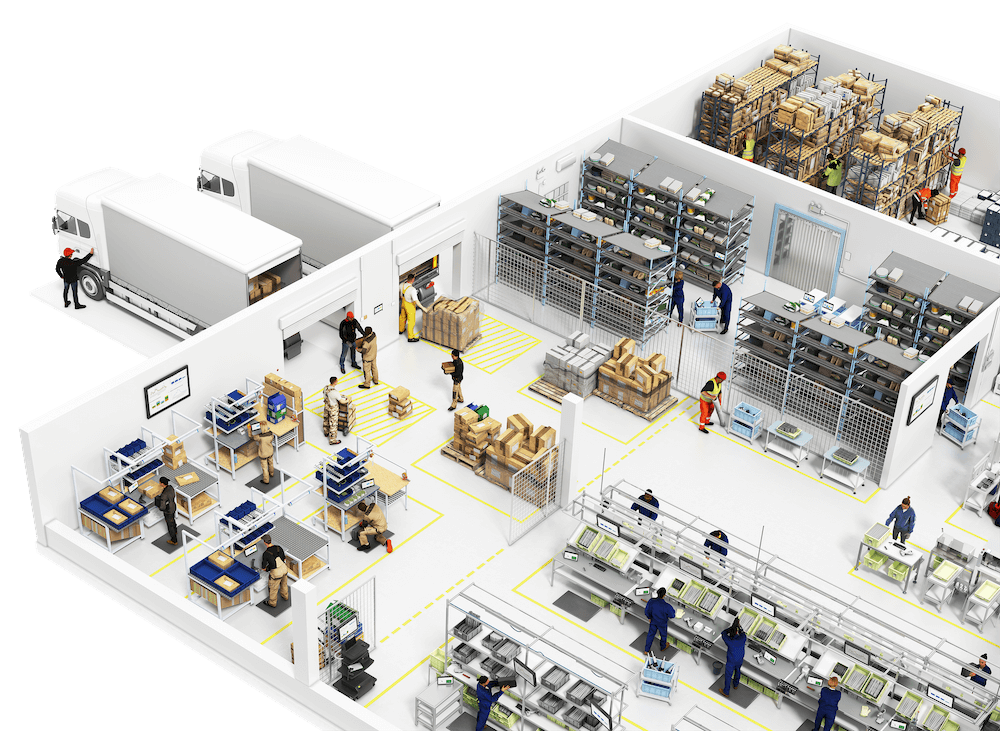

You can find visual information everywhere on the typical shop floor: Machine HMIs (Human-Machine Interfaces), Andon tower lights on every station, shelves, and bins labeled with color and text, floors marked, and tools arranged in shadow boards. Visual information is a strong cue for humans to help them perform tasks efficiently and without mistakes. Visuals can also serve as a way to provide information, for example, a dashboard with a numeric description of the state of the floor or a set of gauges that indicate the machine’s behavior. Unfortunately, much of this information is “locked” in the physical world and is not digitized. This is where Tulip Vision comes in, to help unlock visual information.

For decades, manufacturers have been using cameras on the shop floor to monitor operations. Historically, it has been people that observe the camera feed and make decisions. More recently, manufacturers have started utilizing computer vision and AI to augment human eyeballs to automatically extract insights. However, an enormous amount of visual data is still “pixel locked” to computer screens and HMIs. Legacy machining equipment, inspection machines with proprietary software, and even MES software are ubiquitous on shop floors’ PC screens. Bringing this information to the manufacturing cloud almost always means upgrading it. But replacing legacy equipment with newer more connective gear is not always the right choice. It’s often a bigger expense than the gains the replacement can bring, and in all cases, it results in downtime and re-training - again more capital and operating costs. Finding new ways to connect old equipment can be a key to success.

Digital transformation for lean manufacturing is a journey that requires innovation and creativity, doing more with less. That is why Tulip Vision has added a couple of ways to connect PC visual output - the windows and applications which produce consumable visual data - into streams available for automatic visual analysis. This opens up multiple possibilities for old gear and existing processes that rely on these tools but cannot easily be digitized. Capturing the screen, we can send the pixels to analysis tools such as OCR (Optical Character Recognition) or simple change detections.

Our customer VEKA is overcoming the visual information gap by utilizing Tulip to bridge the old to the new. Veka has used Tulip Vision to capture information from sensors connected to a Windows PC by using network-based screen capturing. Rejuvenating an old system and feeding the information to Tulip (and other systems) with Tulip vision OCR capabilities they’ve granted the equipment a new lease on its value for their operations, extending its lifetime and utility.

To get started with capturing and connecting your shop floor’s visual information, use the following guides:

With digital transformation and lean operations in mind, capturing existing visual information on the shop floor makes perfect sense. Doing more with less, extending the lifetime of existing equipment, and eliminating the need for manual observation of visual cues - all can contribute to improving your operation's bottom-line metrics.

Transform Your Operations with Tulip

Learn how Tulip can help augment your workers' abilities and boost your efficiency and productivity